TEKNO-THERM

INTELLIGENT PASTEURISER

Pasteurisation unit is the heart of a food processing plant. It ensures the heating process according to the technological requirements.

Tekno-therm intelligent pasteuriser is used to produce a wide range of products such as; milk, cream, brine, fruit juice, egg, ketchup, mayyonnaise, beer, honey, vegetable oils and ice cream mix.

Tekno-therm intelligent pasteurisers are in variable capacity from 1.000 L/h to 60.000 L/h.

Depending on the individual production requirements, a wide range of machinery can be coupled with the Tekno-therm intelligent pasteuriser such as; deaerator, bacteria clarifier, cream seperator, automatic standardization unit, homogeniser and holder.

The know-how of Teknoproses engineers and the well-proven GEA components ensure excellent performance.

The effects of Tekno-therm intelligent pasteuriser on your product quality;

• Minimizes the risk of human error with high automation level

• Obtain food safety

• Full traceability

• Standard product quality

Tekno-therm intelligent pasteuriser does the following steps with a SINGLE TOUCH

• Automatic water reception

• Sanitation

• Get the thermal program according to the selected product

• Automatic product receiving

• Automatic CIP after process

With the Tekno-therm intelligent pasteuriser every step of the process is registered in data log.

• Temperature

• Flow rate

• Pressure

• Product-hot water temperature difference

• CIP data

Body components:

• Shuttle valve

• Hot water PHE

• Touch panel

• Frame

• Plate

• Sliding Element

• Temperature Transmitter

• Flowmeter

• Hygienic Balance Tank

• Centrifugal Pump

Tekno-therm intelligent pasteuriser – Energy Saving

• The heat recovery up to 95%

• Minimum steam, water and electricity consumption

• Shorter start-up time

• Longer running time

• Automatic CIP

Tekno-therm intelligent pasteuriser – High Safety Level

• Pasteurizer has standard safety devices that provide higher pressure on the pasteurized product side. There is no risk of un-pasteurised product mix into pasteurized product.

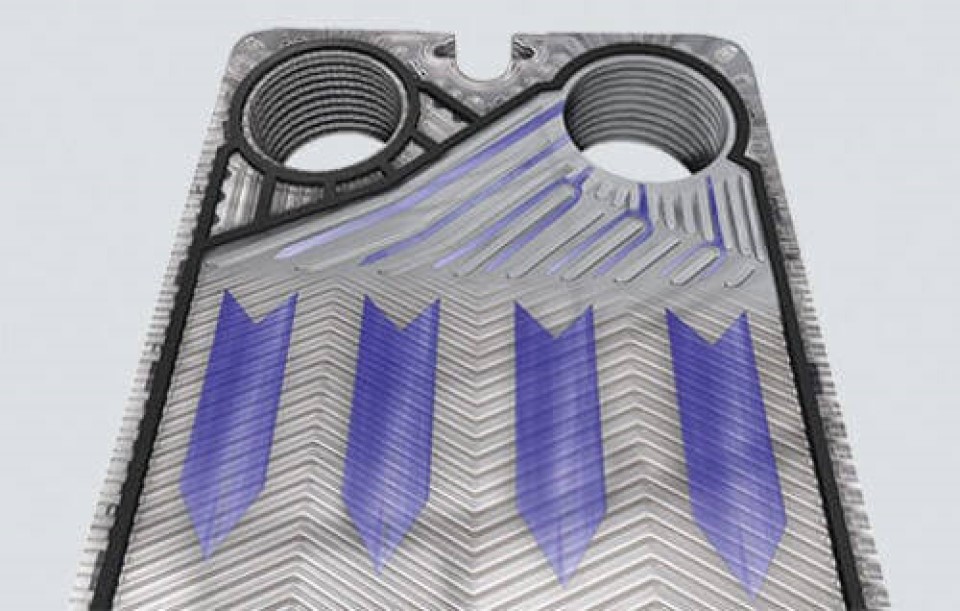

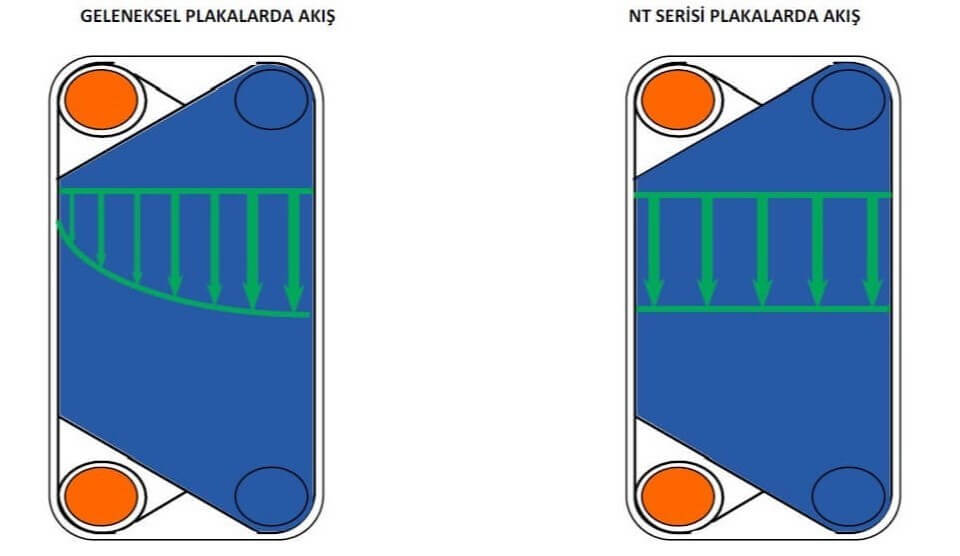

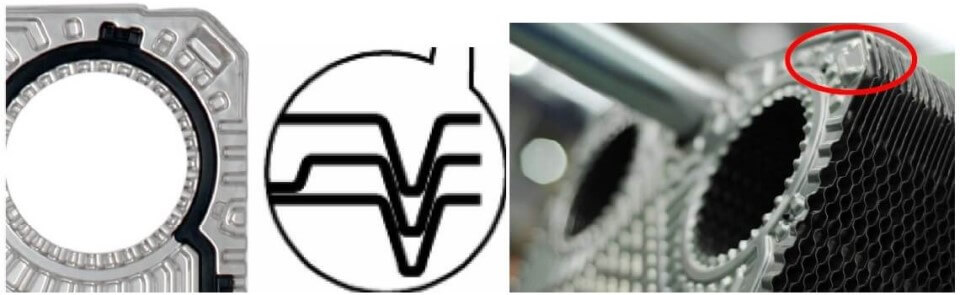

OptiWave Plate Design

• The fluid is homogeneously distributed over the plate surface thanks to the optimized heat exchanger plate pattern. Thus, high heat transfer coefficients are achieved in the plate heat exchanger.

Ecoloc Gasket System

• Thanks to the EcoLoc system, which does not require glue, used in our plate heat exchangers, heat exchanger seals are easily and quickly replaced. This provides an advantage in operating costs.

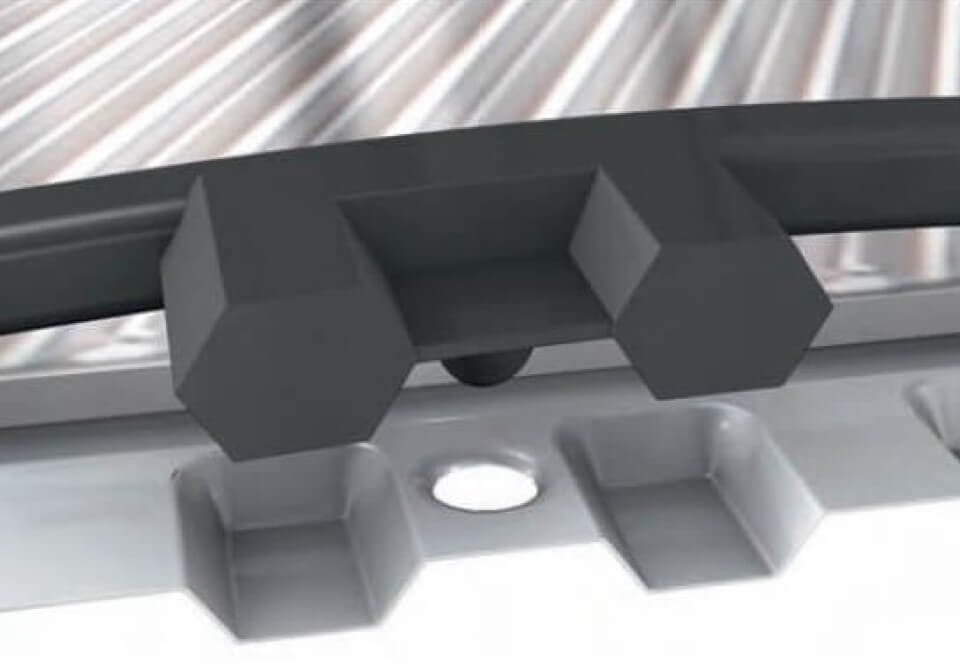

PosLoc Lock System

• The stable heat exchanger plate package obtained by the Posloc system eliminates the risk of damage to the heat exchanger plates and gaskets during maintenance and cleaning processes. In this way, it provides increased service life of heat exchanger seals and plates.