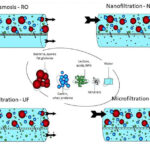

Membrane filtering systems are frequently used in the industry. In many applications, it has replaced more traditional centrifugal separation, evaporation and coagulation to provide significant benefits in terms of efficiency, product quality and sustainability.

UF offers the opportunity to concentrate high molecular weight components without heat application and phase change. In the ultrafiltration method, the filtration process is based on the principle of passing the liquid through a semi-permeable membrane under the influence of hydrostatic pressure. UF membranes are used to obtain pure product or concentrate the product by separating macromolecules, colloidal particles and dispersions.

While high molecular weight solids and dissolved substances are retained, water and low molecular weight dissolved substances pass through the membrane. Suspended solids and high molecular weight solvates are retained in the retentate, while water and low molecular weight solvates pass through the membrane in the permate (filtrate).

Examples of the use of ultrafiltration technology in the dairy industry include standardizing and concentrating proteins, milk powder production, condensed milk production and white cheese production. Ultrafiltration technology, which is widely used in our country in the production of white cheese, keeps the protein and fats by passing lactose, mineral, non-protein nitrogen, water and water-soluble vitamins in milk to be processed into the cheese by means of semi-permeable membranes. Compared with the traditional method, white cheese production with the ultrafiltration technique provides an efficiency increase of approximately 16-20% and saves up to 80% in the use of yeast and starter culture.

With unprofitable ultrafiltration white cheese, a more standard product is provided compared to the traditional method, and the possibility of contamination of coliform group bacteria and mold, yeasts, which pose a risk due to environment, equipment and personnel hygiene, is reduced.

The advantages of using ultrafiltration technique in feta cheese can be listed as follows;

- High efficiency

- Standard product quality

- The weight difference between cheese decreases

- Reduced risk of microbial contamination

- Reduction of raw material costs

- Reduction in equipment, storage and transportation costs

- High capacity, continuous line

- Decrease in environmental pollution

General application advantages of ultrafiltration;

- Low energy consumption

- No heat treatment on milk

- Recycling of fresh water for the enterprise

- Reducing waste treatment cost

- Less space and capital needed

Ultrafiltration application areas;

- Food and Dairy industry;

- Cheese production and standardization of cheese milk

- Production of concentrated dairy products

- Whey powder and milk powder production

- Concentrated yogurt production

- Washing water CIP and product recovery

- In the preparation of product and protein concentrates

- In fruit juices and concentrates

- In ice cream production

- In wastewater treatment systems

- To obtain drinking water from sea water